Aware of the importance of quality to secure the loyalty of its customers and of innovation to remain the leader of this industry, Barbier Group sets up a laboratory for quality control and R&D.

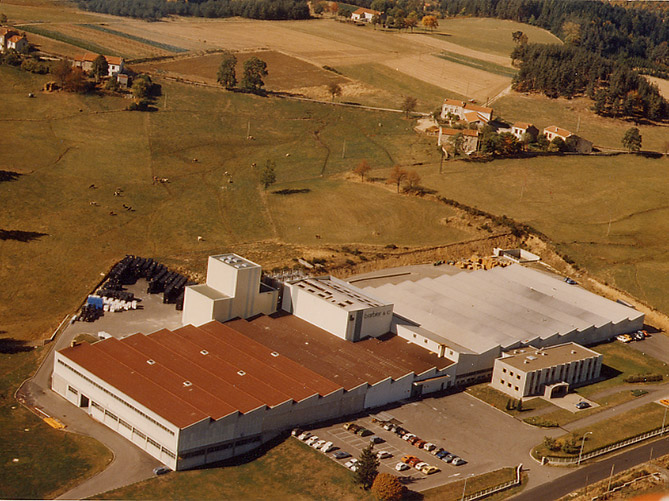

The retail activities of Barbier Group are gathered in the ultramodern plants of Chavanon 1 and Chavanon 2, in Monistrol sur Loire.

Coextrusion is now used for large production runs: 3-layer coextrusion is gradually replacing the mono-layer extrusion.

The production site Chavanon is once again enlarged with Chavanon III a building dedicated to the manufacture of technical coextruded films.

A new department of Chavanon is built in order to meet the growth waste bag sector.

Startup of the manufacturing unit for stretch CAST film (flat process) for the 5 layers wrapping of the pallets and for agricultural stretch film.

This decade also saw the introduction of eco-design products as well as the use of polyethylene of plant origin.

Barbier Group’s products are the first in the industry “to get the “France Origin Guarantee” certification.

From now on coextruded 3, 5, and soon 7 and 9 layer films, produced by Barbier Group, will represent 85 % of the machinery.

Chavanon V, dedicated to the recycling of waste is planned to open in 2015.