STRETCH MULTIPACK for overpack unit packaging.

Barbier Group is proud to be involved to protect the environment. Eco design and thicknesses reduction are among our primary objectives and priorities.

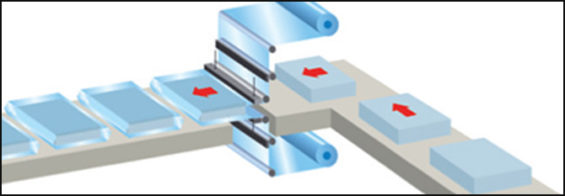

MULTIPACK STRETCH FILM: HOW IT WORKS

Packaging unit is pushed through the curtain film system of the machine.

Pushing system, film’s stretching units and lateral welding are operated by a servomotor and can work synchronously in a very specific set report. In this way we can get packaging stretching without having later to go through a shrink tunnel.

Pushing system moves packaging trough the curtain film.

During the whole operation, stretching units continuously stretch the packaging film depending on the introduction and on the lateral welding.

Lateral welding includes preheated flat welding system associated with mechanical cutting.

Welding and cooling time are electronically operated.

BENEFITS :

- Thicknesses reduction,

- Off line and on line printing possibility

- On line pre cutting

- Completely tightened packaging without additional retraction

- Speed increasing to reach 40 strokes per minute.

- No shrink oven,

- Cost savings up to 15 %.

DISADVANTAGES:

Printing deformation.

TECHNICAL CARACTHERISTICS

Possible product formats:

- length = from 40 mm to 520 mmwidth = from 80 mm to 1 450 mmheight = from 30 mm to 400 mm